Compact

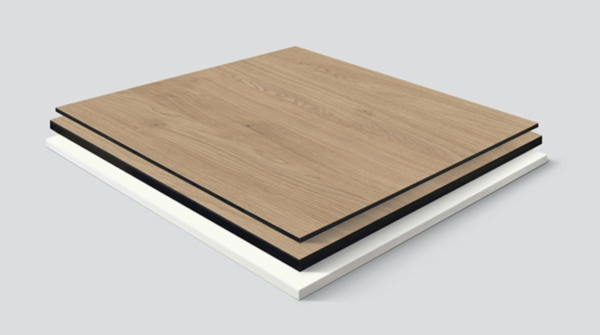

ALFAICA Compact Grade Laminates (HPL) are high-density panels manufactured by bonding multiple layers of specially treated kraft paper with decorative faces under high heat and pressure. This advanced process creates a solid, non-porous compact laminate sheet with exceptional strength, durability, and dimensional stability.

| Sizes | 1220 x 2440 & 1300 x 3050mm |

|---|---|

| Thickness | 2.5mm to 20mm |

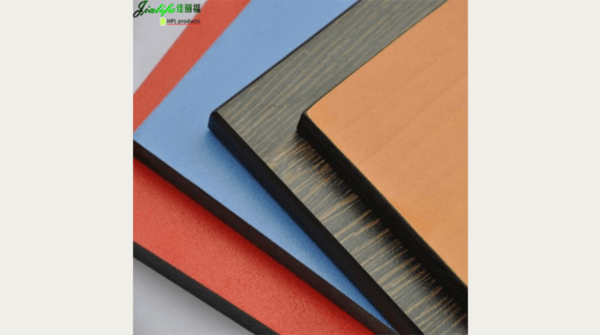

| Finishes | Selection of several finishes |

As a trusted compact laminate manufacturer, ALFAICA designs compacts that can be used both as a substrate and as a finished surface. These compact laminates are suitable for horizontal and vertical grade applications, offering excellent resistance to moisture, impact, heat, and wear. Our products are widely used across commercial, institutional, and high-traffic environments.

Key Features & Applications

- Premium-quality compact laminate sheets for heavy-duty use

- Suitable for both horizontal and vertical applications

- Ideal for washrooms, partitions, lockers, laboratory furniture, and wall cladding

- High resistance to moisture, chemicals, heat, and impact

- Long-lasting performance with minimal maintenance

- Manufactured using advanced technology and quality-controlled processes

- Trusted by architects, designers, and builders as reliable compact laminate suppliers

- Designed to meet national and international quality standards

| Sr No | Properties | Unit | Requirement as per EN438:2005 | Alfaica Conforms |

|---|---|---|---|---|

| 1 | Length / Width | 2440 x 1220 mm 3050 x 1300 mm |

(± 10, - 0 mm) (± 10, - 0 mm) |

(± 10, - 0 mm) (± 10, - 0 mm) |

| 2 | Appearance | - | Should be free from foreign particles | YES |

| 3 | Density | gm/cm³ | > 1.35 | 1.4 |

| 4 | Dimensional stability | % Max – “L” % Max – “T” |

0.3 0.6 |

√ √ |

| 5 | Wear Resistance | Cycles(min) | 350 | 400 |

| 6 | Resistance to dry heat @ 180℃ | Grade | 3 | ≥3 |

| 7 | Boiling water Resistance | Mass Increase % (max) Thickness Increase % (max) |

2 2 |

1 1 |

8 | Resistance to water Vapour | Appearance | 4 | ≥4 |

| 9 | Resistance to Cigarette Burn | Grade | 3 | >3 |

| 10 | Resistance to impact By large diameter Ball | Drop Height (mm) Indent Diameter (mm) |

800 10 |

> 1000 No Dent |

| 11 | Resistance to Crazing @ 80℃ in Oven | Appearance | 4 | ≥4 |

| 12 | Resistance to Staining | Appearance Group 1 & 2 Group 3 |

5 4 |

5 >4 |